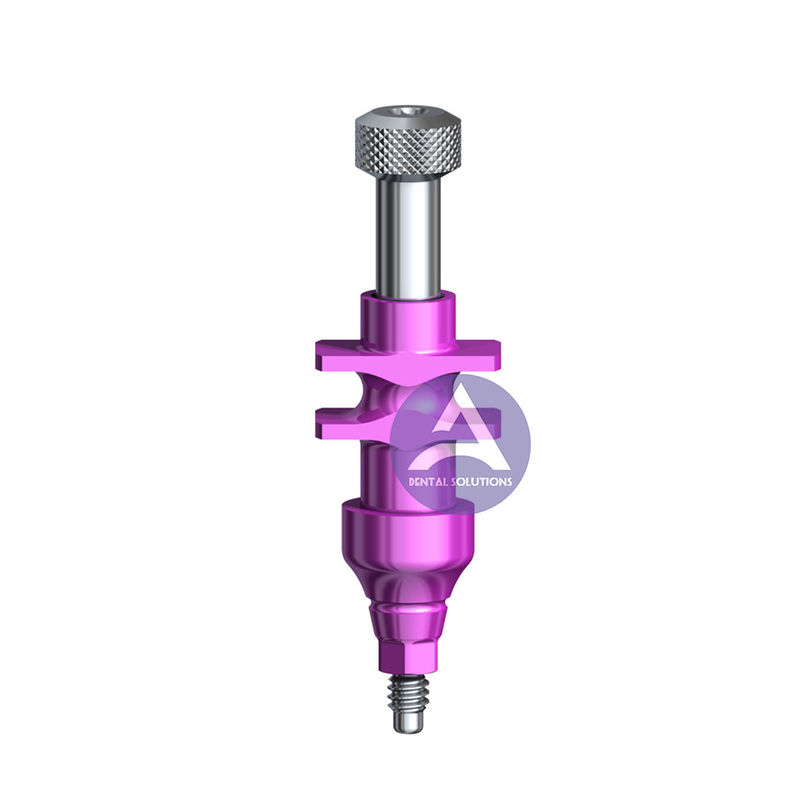

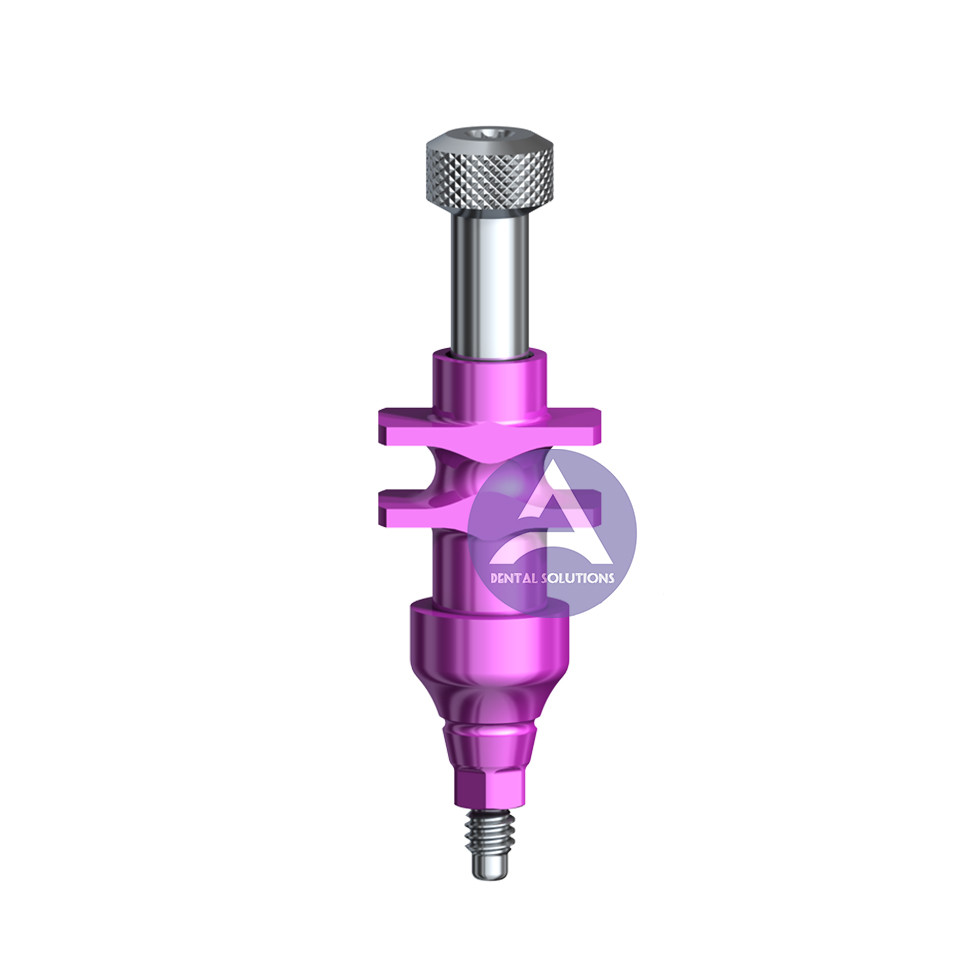

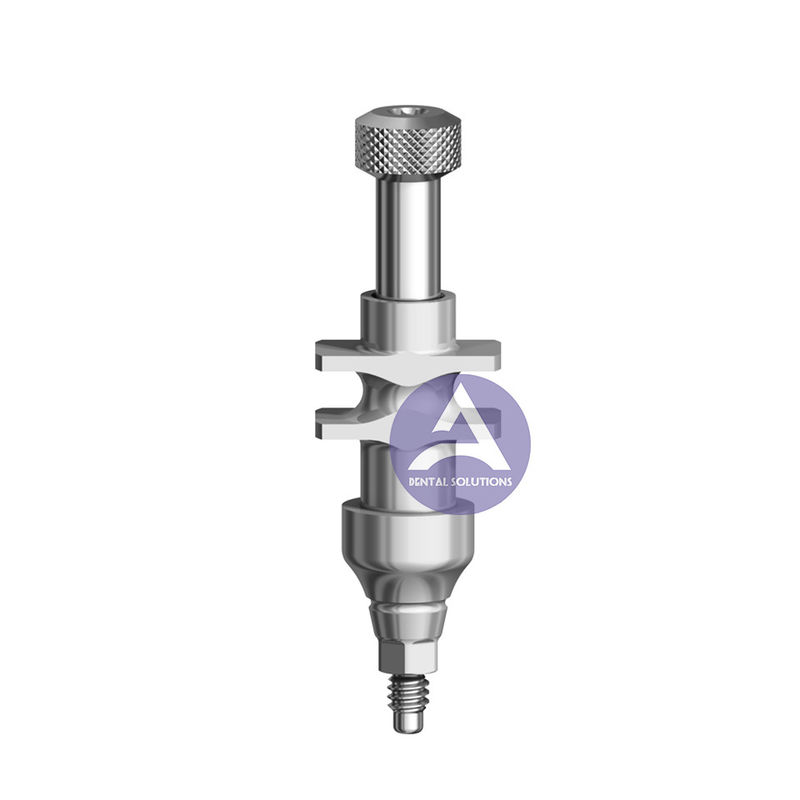

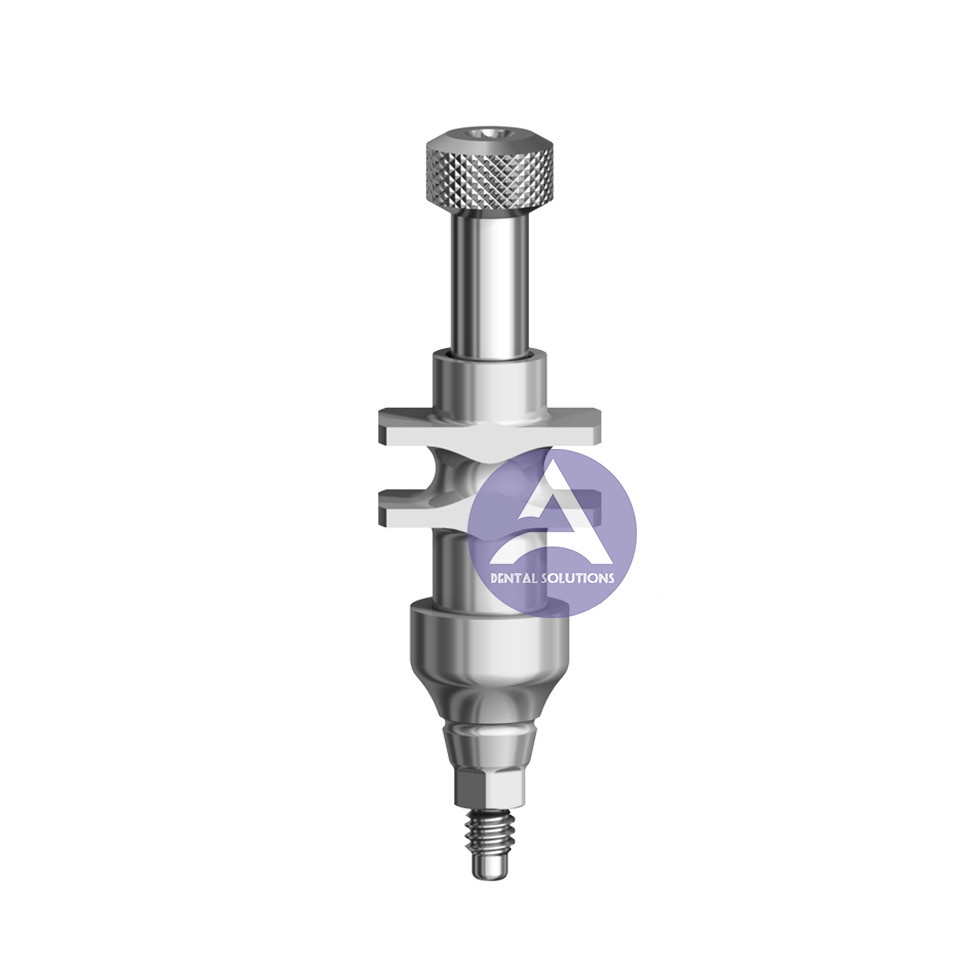

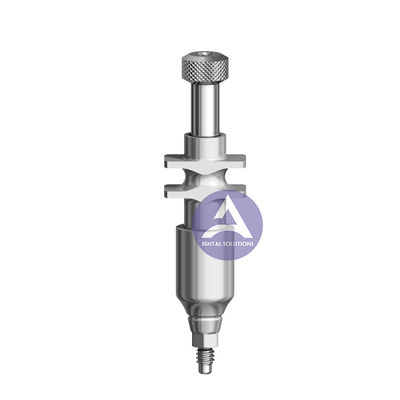

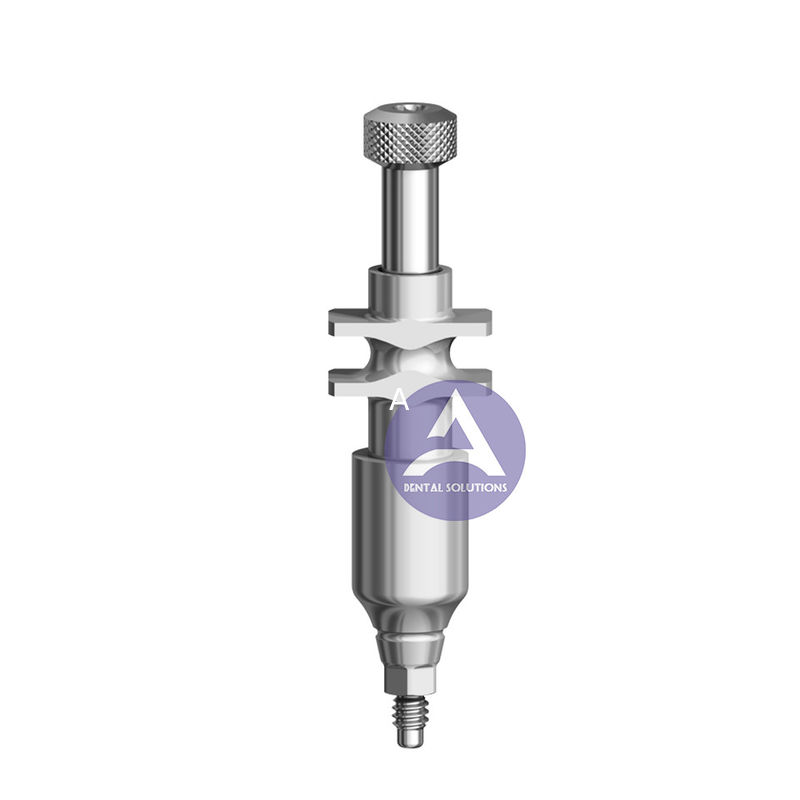

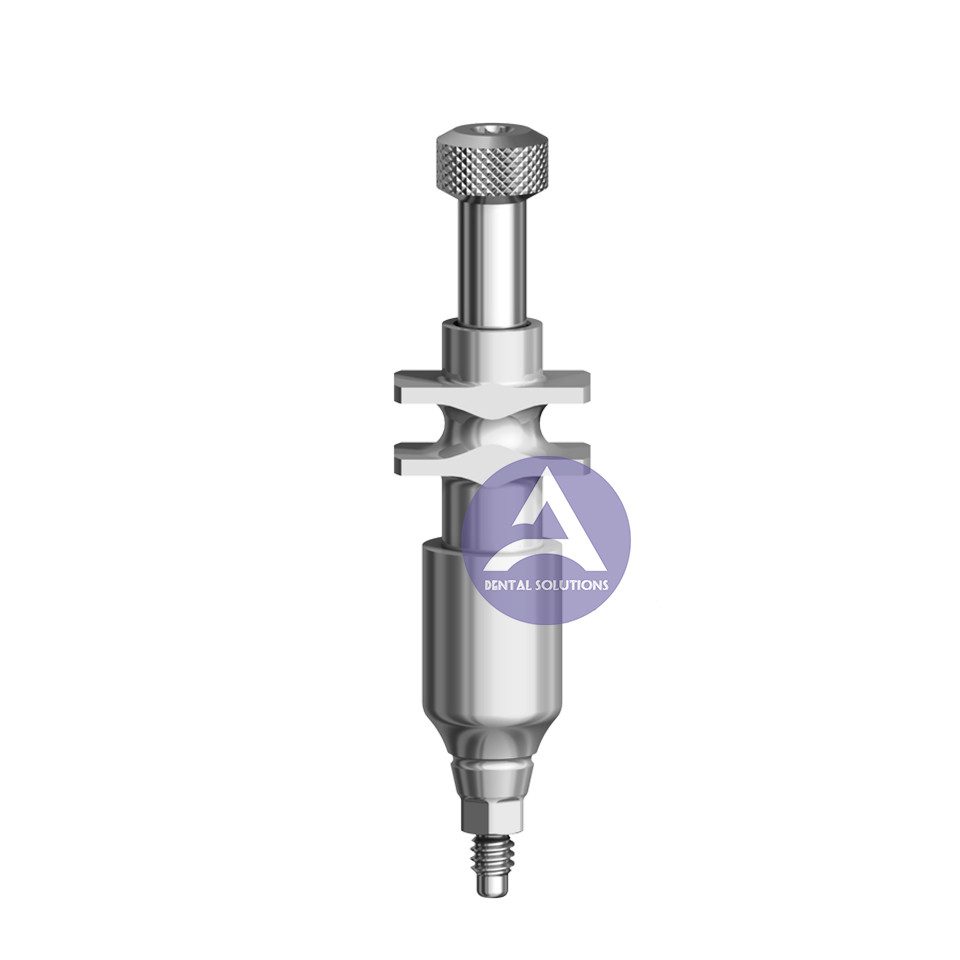

Nobel Active Impression Coping Open Tray Conical

Connection NP Ø 5 x 10mm/14mm

Material:

Ti 6AI-4V ELI (Supply from Germany)

Reference Number:

36259

36261

Feature:

- Titanium interface abutment

- Precision machined up to ± 5µm

- Combination of high fatigue strength

- Superior level of biocompatibility

- Exterior retentions for more cementation bonding

Approved by CE, ISO 9001, ISO 13485

| Length |

10 / 14 mm |

| Implant Platform |

Narrow Platform (NP) |

| Diameter |

5 mm |

| Material |

Titanium Alloy |

| Indication |

Single-unit |

| Connection Type |

Internal Conical Connection |

| Open or Closed Tray |

Open Tray |

| Works with |

NobelActive, NobelActive TiUltra, NobelParallel CC, NobelParallel CC TiUltra, NobelReplace CC, NobelReplace CC PMC |

| Purpose |

CAD/CAM prosthetic, Pre-fab prosthetic

|

NobelActive™

Fig. 3

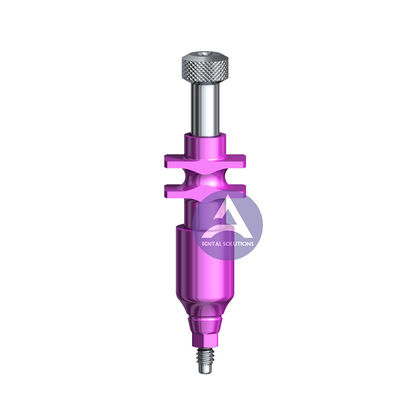

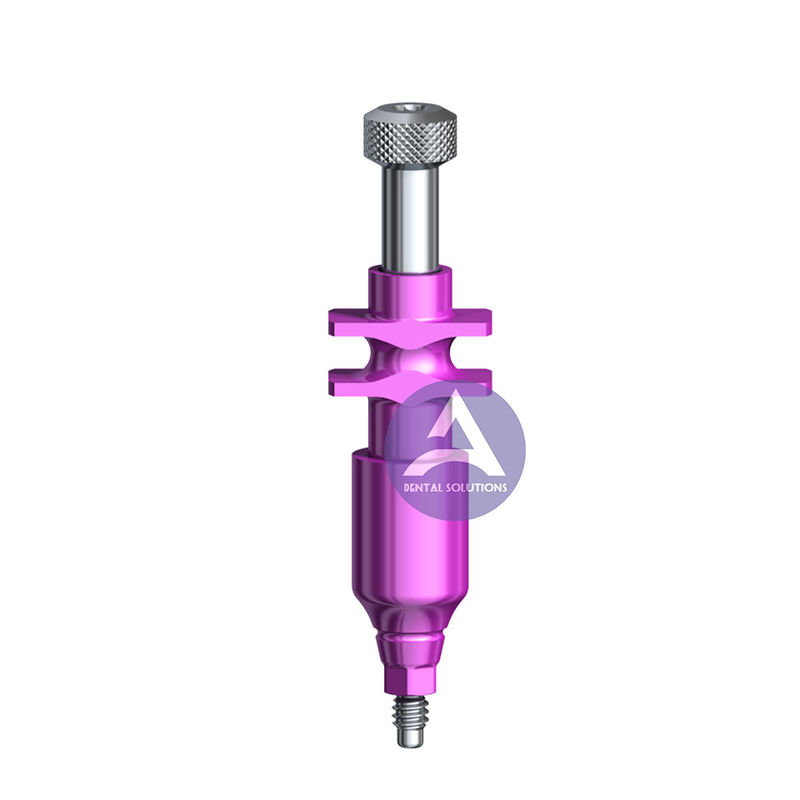

Direct impression copings designed for the open tray impression technique are produced in two emergence profiles for NP platform implants (Fig.3, top row) and three emergence profiles for RP implants (Fig.3, bottom row). NP impression copings are produced in one height of 14mm while RP impression copings are available in two heights, 14m and a low profile version of 10mm. Emergence profiles for NP impression copings are machined in 3.6 and 5.0mm. RP impression copings are offered in three emergence profiles of 3.6, 5.0 and 6.0mm Only NP (3.5mm) platform impression copings are color coded for identification (fuchsia). A Unigrip™ driver may be used to service the fixation screw for impression copings.

Brånemark System™, NobelSpeedy™

Fig. 3

All of the implants in this product group are machined with a external indexing feature (Fig.3) in four implant/abutment platform diameters of 3.5 (NP, narrow platform), 4.1 (RP, regular platform), 5.0 (WP, wide platform). The indexing feature consists of a external hexagon design of platform diameter specific dimensions, making prosthetic components incompatible from platform diameter to platform diameter. No color coding is evident for platform diameter identification on any of the external hex implants.

Fig. 4

Brånemark System™ MK III TiUnite® implants (Fig.4) are offered in one body geometry, parallel walled with a diminishing thread depth toward the apical of the implant. A 0.7mm machined collar separates the implant/abutment interface from the TiUnite® treated surface area of the implant. Cutting flutes incorporated at the apex of the implant (Fig.5) give this implant design self tapping capabilities. 3.5mm platform implants are produced in four (10, 11.5, 13, 15mm) lengths and one implant body diameter of 3.3mm while 4.1 implant/abutment platform diameter implants are produced in two implant body diameters of 3.75 and 4.0mm

Fig. 5

and three additional lengths of 7, 8.5 and 18mm. 5.1mm platform diameter implants are offered in one body diameter of 5mm and seven lengths.(7, 8.5, 10, 11.5, 13, 15 and 18mm) . Although each implant in this product group is actually 0.5mm shorter than advertised and the advertised length does not include the 0.7mm height of the indexing hex at the top of the implant. No 6mm diameter implant is available within this group. Cover screws are included in this product group.

Fig. 6

Brånemark System™ MK III Groovy implants (Fig.6) are offered in one body geometry, parallel walled with a diminishing thread depth toward the apical of the implant and a secondary groove underneath each thread to enhance initial stability. The implant surface treatment extends from the edge of the implant/abutment junction uniformly to the apex without any machined collar. Cutting flutes incorporated at the apex of the implant (Fig.7) give this implant design self tapping capabilities. 3.5mm platform implants are produced in four (10, 11.5, 13, 15mm) lengths and one implant body diameter of 3.3mm while 4.1 implant/abutment platform diameter implants are produced in two implant body diameters of 3.75 and 4.0mm and three

Fig. 7

additional lengths of 7, 8.5 and 18mm. 5.1mm platform diameter implants are offered in one body diameter of 5mm and seven lengths (7, 8.5, 10, 11.5, 13, 15 and 18mm). Although each implant in this product group is actually 0.5mm shorter than advertised and the advertised length does not include the 0.7mm height of the indexing hex at the top of the implant. No 6mm diameter implant is available within this system. Cover screws are not included in this product group.

Fig. 8

Brånemark System™ MK IV TiUnite® implants (Fig.8) are offered in one body geometry, parallel walled with a diminishing thread depth toward the apical of the implant. Cutting flutes incorporated at the apex (Fig.9) of the implant give this implant design self tapping capabilities. 4.1mm platform implants are produced in one implant body diameter of 4.0mm with a 0.4mm collar in seven (7, 8.5, 10, 11.5, 13, 15 and 18mm) lengths. 5.1mm platform

Fig. 9

diameter implants are machined with a 0.2mm collar and a body diameter of 5mm and the same seven lengths as 4.1mm platform implants. Each implant in this product group is actually 0.5mm shorter than advertised and the advertised length does not include the 0.7mm height of the indexing hex at the top of the implant. Cover screws are included in this product group.

Fig. 10

NobelSpeedy™ Groovy (Fig.10) implants are offered in one body geometry, parallel walled with a tapered apex. The thread pattern has a secondary groove underneath the primary thread and the threads are carried all the way to the apex of the implant. Cutting flutes incorporated at the apex of the implant (Fig.11) give this implant design self tapping capabilities. The TiUnite® surface treatment extends from the edge of the implant/abutment interface all the way to the apex of the implant. 3.5mm platform implants are produced in four (10, 11.5, 13, 15mm) lengths and one implant body diameter of 3.35mm while 4.1mm platform implants are produced in one implant body diameter of 4.0mm in seven (7, 8.5, 10,

Fig. 11

11.5, 13, 15 and 18mm) lengths. 5.1mm platform diameter implants are machined in two configurations. Either with a body diameter of 5mm and the same seven lengths as 4.1mm platform implants and a body diameter of 6mm also in seven (7, 8.5, 10, 11.5, 13, 15 and 18mm) lengths. Each implant in this product group is actually 0.5mm shorter than advertised and the advertised length does not include the 0.7mm height of the indexing hex at the top of the implant.Cover screws are not included in this product group.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!